CII Research Laboratories

Structural Engineering Research Laboratory (SERL)

Directed by Dr. Mohamed ElGawady

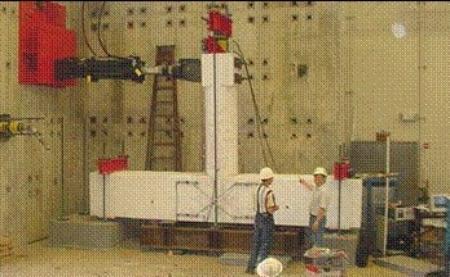

The SERL facility in the Department of Civil, Architectural, and Environmental Engineering (CArEE) at Missouri S&T is a research/education complex that includes a high bay structural testing laboratory, a materials laboratory, and a machine shop. The high bay structural testing laboratory is approximately 35 m long and 22 m wide, having a total of 770 m2 usable floor areas for testing and evaluation of large- and full-scale structural components and structural systems (see Figs. 4 and 5). It features a fixed L-shaped reaction wall that is 5.5 m in height and a 20-ton overhead crane with a vertical clearance of 6 m. A twin tunnel basement under the 258 m2 strong floor facilitates the anchorage of testing specimens and instrumentation setups. Connected to the high bay structural testing laboratory is a materials laboratory (831 m2 total) used for the preparation of structural specimens and related materials testing and a machine shop that supports the fabrication of custom-made equipment and test specimens.

The SERL houses an MTS 840 shake table capable of simulating one-dimensional earthquake excitations. The table platform measures 1.2 m × 2.1 m in plan and can support a payload of 90 kN. With internal control, the shake table can simulate various displacement patterns such as sine, ramp, and random waveforms. With external control, it can replicate ground motions recorded during actual earthquakes. The shake table can produce a maximum acceleration of 1.0 g, a maximum velocity of 610 mm/sec, and a peak stroke of ±25.4 mm in an operational frequency range of 0.1-10 Hz.

The SERL is equipped with four large hydraulic actuators with servo-controlled valves for pseudo-static testing, including two MTS 490 kN units with ±610 mm stroke capacity, and two MTS 1.8 MN unit with ±610 mm stroke capacity. In addition, one actuator, an MTS 490 kN unit with +/-610 mm stroke capacity, is available for fatigue testing. The actuators can be operated at a maximum speed of 0.1 m/sec. To complement these actuators, hydraulic service manifolds, one 350-liter/m hydraulic power pump, and one MTS-493.05 FlexTest GT electronic control system are available. A 128-channel high-capacity data acquisition system (DAS) is available for this project. This system has capacity for expansion to 256 channels. Figs. 4 and 5 show two large-scale tests with the use of the L-shaped reaction wall and the modular frame set on the strong floor.

The SERL also includes an MTS 880 universal testing machine (556 kN loading capacity and ±152.4 mm stroke), a Tinius-Olsen L120000 loading machine (600 kN capacity), and a Baldwin/Forney testing machine (2,224 kN capacity and 254 mm stroke). Together with the MTS880 testing machine, the Camac crate with a PC can be used to record 64 channels of streaming data at the rate of 1.0 MHz. The laboratory is equipped with a 32-channel data acquisition system capable of streaming data at 100 kHz. The data acquisition system can be interfaced with the Tinius-Olsen and Baldwin loading machines.

Fig. 4 Large Scale Beam-Column Joint

Fig. 5 Full Scale Bridge Deck Tested to Failure

Follow Center for Intelligent Infrastructure